University certificate

The world's largest faculty of nutrition”

Introduction to the Program

Con esta Postgraduate diploma 100% online podrás estar al día en Enzimología y Gestión Empresarial”

La Industria Alimentaria ha sabido en los últimos años sacar un enorme potencial al empleo de determinadas enzimas ya sean de origen vegetal, animal o microbiano en la elaboración de sus productos. Ello ha potenciado la enzimología, la mejora en la conversación de los alimentos, así como la aparición de los productos nutracénicos o funcionales. Un panorama de innovación, donde proliferan los estudios que cuyo objetivo es la mejora de la salud a través del uso de enzimas en alimentos.

Así, los nuevos procedimientos biotecnológicos, las novedosas aplicaciones de las enzimas en la producción de aditivos y su uso en el sector alimentario obligan al profesional de la Nutrición a estar en constante actualización de sus conocimientos. Es por ello, por lo que TECH ha creado esta Postgraduate diploma en Enzymology Applied to the Food Industry, el cual ofrece la información más reciente en este ámbito, gracias a las aportaciones realizadas por especialistas de este campo.

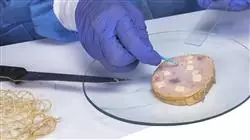

Un programa 100% online, que le permitirá al alumnado ahondar en los fundamentos de la ingeniería química, adentrarse en los avances más recientes de la tecnología enzimática o al desarrollo de nuevos procesos y productos en el ámbito de la carne, el pescado y sus derivados. Todo ello además complementado con vídeo resúmenes de cada tema, vídeos en detalle, simulaciones de casos de estudio o lecturas esenciales a las que podrá acceder las 24 horas del día.

El profesional está así, ante una excelente oportunidad, de poder estar al día en enzimología a través de una titulación universitaria flexible, cuyo contenido podrá visualizar fácilmente desde cualquier dispositivo con conexión a internet. Además, el alumnado cuenta con el sistema Relearning, empleado por TECH, que le permitirá reducir las largas horas de estudio y avanzar de un modo mucho más ágil por el temario de esta Postgraduate diploma.

Adéntrate con esta titulación en la información más destacada y reciente sobre la Enzymology Applied to the Food Industry”

Esta Postgraduate diploma en Enzymology Applied to the Food Industry contiene el programa científico más completo y actualizado del mercado. Sus características más destacadas son:

- El desarrollo de casos prácticos presentados por expertos en Tecnología de Alimentos

- Los contenidos gráficos, esquemáticos y eminentemente prácticos con los que está concebido recogen una información científica y práctica sobre aquellas disciplinas indispensables para el ejercicio profesional

- Los ejercicios prácticos donde realizar el proceso de autoevaluación para mejorar el aprendizaje

- Su especial hincapié en metodologías innovadoras

- Las lecciones teóricas, preguntas al experto, foros de discusión de temas controvertidos y trabajos de reflexión individual

- La disponibilidad de acceso a los contenidos desde cualquier dispositivo fijo o portátil con conexión a internet

Cuentas con una biblioteca de recursos amplia con la que podrás consultar cuando quieras, la información más reciente sobre los cálculos de estimación de vida útil de los alimentos”

El programa incluye, en su cuadro docente, a profesionales del sector que vierten en esta capacitación la experiencia de su trabajo, además de reconocidos especialistas de sociedades de referencia y universidades de prestigio.

Su contenido multimedia, elaborado con la última tecnología educativa, permitirá al profesional un aprendizaje situado y contextual, es decir, un entorno simulado que proporcionará una capacitación inmersiva programada para entrenarse ante situaciones reales.

El diseño de este programa se centra en el Aprendizaje Basado en Problemas, mediante el cual el profesional deberá tratar de resolver las distintas situaciones de práctica profesional que se le planteen a lo largo del curso académico. Para ello, contará con la ayuda de un novedoso sistema de vídeo interactivo realizado por reconocidos expertos.

Gracias a esta Postgraduate diploma podrás conocer los últimos avances en el desarrollo de nuevos procesos y productos en el ámbito de la carne, el pescado y sus derivados”

Accede cuando lo desees, desde tu ordenador o Tablet a la información más reciente sobre medioambiente, calidad y el uso enzimas”

Syllabus

This Postgraduate diploma has been developed by experts in Enzymology Applied to the Food Industry. His extensive knowledge is reflected in the 3 modules that make up the structure of this university degree. Through it, students will be able to keep abreast of the latest developments in the enzymatic modification of carbohydrates, lipids or proteins. Likewise, you will be able to delve into the technology used in the food industry for the preparation and preservation of meat, dairy or fish products. In addition, the Relearning method, based on the repetition of content, will allow you to progress through the content of this program in a much more agile way.

A study plan designed for nutrition professionals who wish to obtain a Postgraduate diploma without neglecting other areas of their lives”

Module 1. Chemical Engineering Fundamentals

1.1. Introduction to Chemical Engineering

1.1.1. The Chemical Process Industry: General Characteristics

1.1.2. Unit and Stage Operations

1.1.3. Stationary and Non-Stationary Regime

1.1.4. International System of Units

1.1.5. The Food Industry, Chemical Engineering and the Environment

1.2. Material Balance in Systems Without Chemical Reaction

1.2.1. General Formula for the Total Material Balance and Applied to a Component

1.2.2. Application of Material Balances: Systems with Bypass Current, Recirculation and Purge

1.2.3. Steady State Systems

1.2.4. Non-Steady State Systems

1.3. Material Balance in Systems with Chemical Reaction

1.3.1. General Concepts: Stoichiometric Equation, Stoichiometric Coefficient, Extensive and Intensive Conversion

1.3.2. Degree of Conversion and Limiting Reactant

1.3.3. Application of the Material Balances to Reactive Systems

1.3.3.1. Reactor/Separator System with Recirculation of Unconverted Reactant

1.3.3.2. Reactor/Separator System with Recirculation and Purge

1.4. Heat Energy Balances

1.4.1. Types of Energy: Formula for Total Energy Balance

1.4.2. Energy balance in Steady State and Non-Steady State Systems

1.4.3. Application of the Energy Balance in Reactive Systems

1.4.4. Heat Energy Balances

1.5. Mechanical Energy Balances

1.5.1. Mechanical Energy Balance

1.5.2. Bernoulli's Equation

1.5.3. Pressure Gauges: Manometers

1.6. Chemical Kinetics and Reactor Engineering

1.6.1. Definitions and Basic Concepts in Applied Chemical Kinetics and Reactor Engineering

1.6.2. Classification of Reactions Expression of Reaction Rate Equations

1.6.3. Study of the Dependence of Velocity on Temperature

1.6.4. Reactor Classification

1.6.4.1. Ideal Reactors: Design Equations and Characteristics

1.6.4.2. Problem Solving

1.7. Velocity Equations in Constant Volume Reactors

1.7.1. Velocity Equations for Elementary Reactions: Integral and Differential Methods

1.7.2. Reversible reactions

1.7.3. Parallel and Series Reactions

1.7.4. Problem Solving

1.8. Reactor Design for the Food Industry

1.8.1. General Characteristics of Reactor

1.8.2. Types of Ideal Reactors

1.8.2.1. Discontinuous Ideal Reactor

1.8.2.2. Steady-State Complete Mix Flow Reactor

1.8.2.3. Stationary Piston Flow Reactor

1.8.3. Comparative Analysis of Reactors

1.8.4. Production: Optimum Reactor Size

1.8.5. Problem Solving

1.9. Chemical Thermodynamics and Solutions

1.9.1. Systems, States and State Functions. Work and heat

1.9.2. Principles of Thermodynamics Enthalpy: Hess' Law

1.9.3. Entropy and Gibs´ Free Energy

1.9.4. Solutions: Solubility and Saturation Solution Concentration

1.10. Chemical Equilibrium

1.10.1. Chemical Equilibrium Reaction Rate and Equilibrium Constant Formula

1.10.2. Types of Equilibria: Homogeneous and Heterogeneous

1.10.3. Displacement of Chemical Equilibrium: Le Chatelier's Principle

1.10.4. Solubility Equilibrium Precipitation Reactions

Module 2. Enzymatic Technology

2.1. Introduction to enzymology

2.1.1. Industrial enzymes: industrial use

2.1.2. Classification of enzymes

2.2. Enzyme kinetics

2.2.1. Enzyme activity units

2.2.2. Stages of an enzymatic reaction

2.2.3. Michaelis-Menten equation: effect of substrate and enzyme concentration. Enzyme efficiency and substrate specificity

2.2.4. Enzyme activity and stability

2.2.4.1. Limitations in practice: pH, temperature, inhibitors, stabilizers and activators. Determination of enzyme activity

2.2.5. Types of enzymatic processes in the food industry

2.3. Enzymatic modification of carbohydrates I

2.3.1. Carbohydrate structure and enzymes that modify carbohydrates

2.3.1.1. Glycosidases: polysaccharidases and disaccharidases

2.3.2.1. Practical examples in the food industry

2.3.2. Obtaining fruit juices: clarified (apple) and cloudy (orange)

2.3.3. Sweetening syrups: glucose, maltose, fructose

2.4. Enzymatic modification of lipids

2.4.1. Enzymology in organic media. Characteristics of lipases

2.4.2. Triglyceride modification

2.4.3. Phospholipid modification

2.4.4. Lipoprotein modification

2.4.5. Synthesis of aromas and flavors

2.5. Enzymatic modifications of proteins

2.5.1. Action of proteases

2.5.2. Factors affecting the activity of proteases

2.5.3. Protein hydrolyzates. Unmoored

2.5.4. Crosslinking: transglutaminase

2.6. Research methodologies in applied enzymology

2.6.1. Biomolecule separation methodologies: Centrifugation, extraction, evaporation and lyophilization

2.6.2. Chromatography of volatile and non-volatile biomolecules: GC and HPLC

2.6.3. Preparative chromatography of enzymes and proteins: FPLC

2.6.4. Proteomics and Metabolomics: Mass spectrometry: maldi-toff

2.7. Agricultural industrial enzymology

2.7.1. Enzymes as molecular targets in agricultural crop improvement

2.7.2. Enzymes applied in post-harvest technology

2.7.2.1. Modified and controlled atmospheres

2.7.2.2. Protective atmospheres

2.7.3. Enzymes applied to food extraction, processing and elaboration

2.7.3.1. Foods fortified with nutraceuticals

2.8. Origin of industrial enzymes

2.8.1. Enzymes isolated from plants, animals, micro-organisms and genetically modified organisms

2.8.2. Main activity and secondary activities

2.8.3. Formulation

2.9. Enzymology and Business Management

2.9.1. Enzymes, industrial property and patents

2.9.2. New technology-based companies, spin offs

2.9.3. Enzymes, prevention and A.P.P.P.C.C. system

2.9.4. Enzymes and environment: ISO 14000 standards, by-products and contaminants

2.9.5. Enzymes and quality: enzymes, ISO standards, GP. Integrated management

2.10. Applied enzymology

2.10.1. Enzymes and Biotechnology Sectors

2.10.2. Enzymes and biocatalysis: Production, bioanalysis, biodegradation and synthesis

2.10.3. Biotechnological production and improvement of enzymes

2.10.4. Homogeneous and heterogeneous enzymatic biocatalysis: Activity, stability, non-aqueous media, immobilization, bioreactors and biosensors

Module 3. Science and Technology of meat, fish and fish products

3.1. Introduction to the muscle food industry

3.1.1. Muscle-based food industries: meat and fish

3.1.1.1. Structural and functional basis of striated muscle

3.1.1.2. Importance of these subsectors

3.1.2. Transformation of muscle into flesh: development of rigor mortis

3.1.2.1. Consequences of rigor mortis

3.1.3. Meat maturation: changes in muscle structure and other nitrogenous compounds

3.1.3.1. Endogenous proteolytic enzymes

3.1.3.2. Optimal ripening conditions

3.2. Anomalous processes in meat processing

3.2.1. Effect of antemortem stress: DFD meats and PSE pork meats

3.2.1.1. Defective sensory characteristics and technological suitability

3.2.1.2. Effect of the administration of growth promoters

3.2.2. Effect of postmortem refrigeration: shortening due to cold

3.2.2.1. Consequences

3.3. Meat quality

3.3.1. Sensory parameters that determine it: color, texture, odor, flavor and water retention capacity of the meat

3.3.1.1. Pre- and post-mortem factors influencing this

3.3.2. Quality measurement and evaluation methods

3.3.2.1. Integrated evaluation of meat quality and technological suitability

3.3.2.2. Quality measurement and evaluation methods

3.3.3. Quality assurance systems in the meat industry

3.4. Industrial meat processing

3.4.1. Animal slaughtering, dressing and carcass preparation technology

3.4.1.1. Channel Classification

3.4.1.2. Electrical stimulation of the carcasses

3.4.1.3. Quartering and categorization

3.4.1.4. Industrial pork carcass cutting

3.4.2. Characteristics of industrial cattle, sheep, pig and poultry slaughterhouses

3.4.3. Systems used in the short term preservation of meat

3.4.3.1. Industrial equipment

3.4.3.2. Shelf life of meat; factors that determine and improve shelf life

3.4.4. Meat freezing

3.4.4.1. Industrial equipment

3.4.4.2. Effects of freezing on sensory and technological properties of meat

3.4.4.3. Defrosting

3.5. Meat packaging and sale

3.5.1. Packaging systems; application to meat preservation and different types of meat sales

3.5.2. Storage under vacuum and in modified atmospheres

3.5.3. Packaging materials

3.5.4. Distribution and sales systems

3.6. Introduction to the fishing and seafood industry

3.6.1. Variability in composition and its causes

3.6.1.1. Classification of fish according to its composition

3.6.1.2. Peculiarities of fish lipids and their importance in technology

3.6.1.3. Fish and seafood connective tissue

3.6.2. Stunning and slaughtering methods: effects on quality

3.6.2.1. Postmortem processing in fish

3.6.3. Differential characteristics of rigor mortis

3.6.4. Most important parameters and their control

3.7. Fish quality

3.7.1. Influence of fishery-related factors on fish quality

3.7.1.1. Main parameters of fish organoleptic quality

3.7.2. Indices for determining the quality and freshness of fish and shellfish

3.7.3. Methods of fish refrigeration

3.7.3.1. Ice: types and effects

3.7.3.2. Freezing: freezing speed and its influence on product quality

3.7.3.3. Freezing maintenance: critical points and their control. Defrosting

3.7.4. Fish and seafood packaging and preservation

3.7.4.1. Vacuum and modified atmospheres

3.7.4.2. Packaging systems and equipment

3.8. Meat derivatives technology

3.8.1. Classification of meat derivatives according to their technological process

3.8.1.1. Preparation, preservation and processing operations

3.8.1.2. Salting, nitrification, drying, heat treatment and smoking

3.8.1.3. Spicing, refrigeration, microbial processes, ripening and chopping

3.8.1.4. Mixing, emulsifying, gelling, stuffing and packaging, etc

3.8.2. General decision and control criteria

3.8.3. Additives and other ingredients used in the meat industry

3.8.3.1. Technological adjuvants

3.8.3.2. Chemical preservatives and sensory modifiers

3.8.3.3. Mass and multifunction agents

3.8.4. Criteria for use in relation to product quality

3.9. Technology of raw cured and cooked meat products

3.9.1. Whole cured meat products: cured ham and similar products

3.9.2. Impact of raw material quality on the final product. Formulation

3.9.2.1. Phases of the elaboration process

3.9.2.2. Modifications undergone during ripening and desiccation

3.9.2.3. Industrial equipment

3.9.3. Decision criteria and process control

3.9.3.1. Defects and alterations

3.9.3.2. Other whole cured products

3.9.4. Cured raw sausages. Formulation criteria

3.9.4.1. Phases and alternatives of the elaboration process

3.9.4.2. Industrial equipment

3.9.4.3. Modifications undergone during ripening and desiccation

3.9.5. Decision criteria and process control

3.10. Fish and fish product technology

3.10.1. Fish preservation by salting

3.10.2. Salting methods. Types and characteristics of salt

3.10.3. Most frequent defects: causes and solutions

3.10.4. Preparation of salted codfish

3.10.5. Fish smoking

3.10.5.1. Smoking systems. Types of smoke

3.10.5.2. Processing methods: advantages and disadvantages

3.10.5.3. Specific products: food quality and safety

3.10.6. Canned tuna. Most important species: characteristics

3.10.6.1. Elaboration process

3.10.6.2. Semi-preserved fish. Salted anchovy. Marinades and pickling

3.10.7. Surimi and derived products

3.10.7.1. Surimi elaboration process

3.10.7.2. Gelation: characteristics and products

3.10.7.3. Crab analogs manufacturing process technology

Thanks to this 100% online university degree you will be up to date with enzymatic processes in the food industry”

Postgraduate Diploma in Enzymology Applied to the Food Industry

Enzymology is a scientific discipline that studies the structure, function and application of enzymes in biological systems. In the food industry, applied enzymology plays a fundamental role in improving production processes, product quality and cost reduction. At TECH Global University we have a complete Postgraduate Diploma in Enzymology Applied to the Food Industry, which aims to provide professionals with the necessary knowledge to understand the basic principles of this field. Here, we offer you from flexible classes that easily adapt to your routine, to an unparalleled methodology that will allow you to internalize the knowledge in a more efficient and productive way. The program consists of several modules, through which you will learn aspects such as the structure and function of enzymes, their relationship with enzyme kinetics and their application in the food industry. In addition, you will address enzyme production, enzyme purification or characterization and their application in food processing.

Learn about enzymology applied to the food industry

This program offers you significant advantages, among them, 100% self-regulated classes, highly efficient pedagogy schemes and interactive content that synthesizes the most sophisticated of enzymology applied to the food industry. With the curriculum, you will learn about the structure and function of enzymes and their relationship to enzyme kinetics. You will also delve into the methods of enzyme production, purification and characterization. Because of this, you will obtain highly valued skills in the food industry, which will allow you to contribute to the innovation and continuous improvement of production processes. What are you waiting for to enroll? Do it now and be part of the largest digital academic community in the world - we are waiting for you!